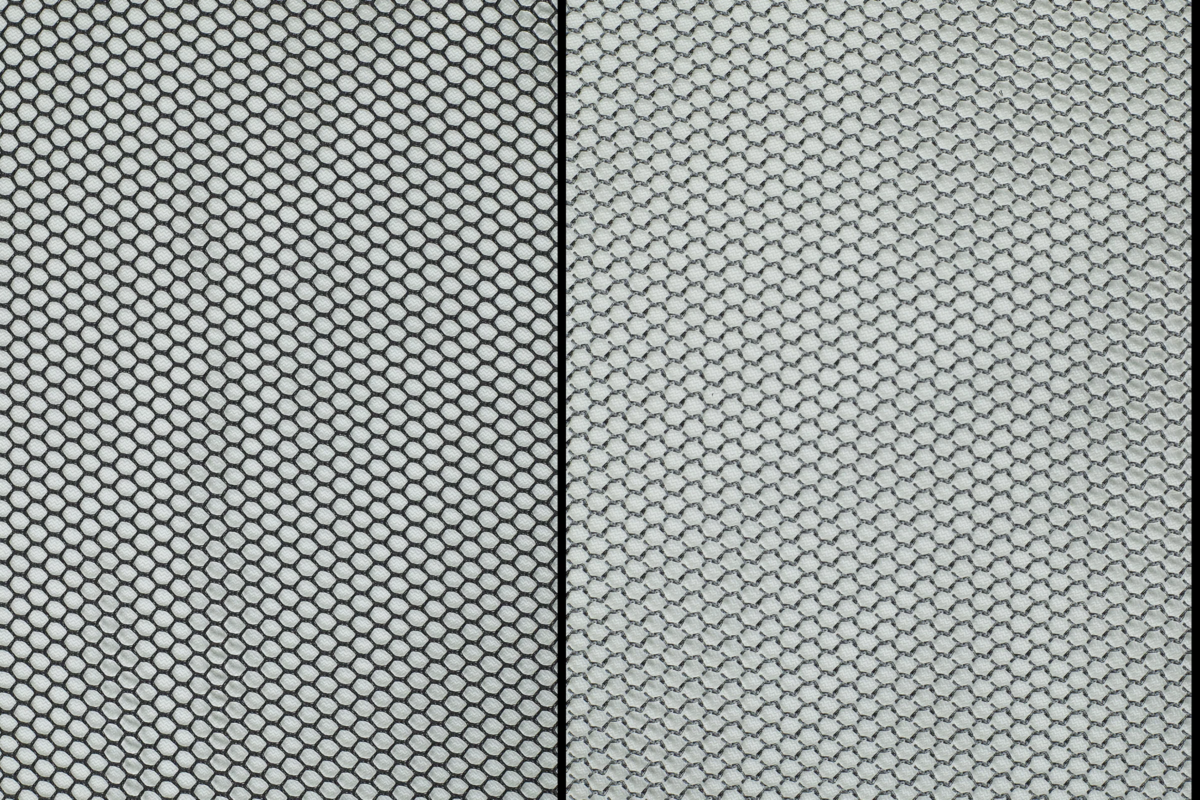

Polyester mesh fabric is a multipurpose textile fabric that may be used for everything from sportswear to industrial filtration. Several manufacturers use it because of its strength, resilience to different environmental conditions, and durability. Given the abundance of possibilities, choosing the ideal polyester mesh fabric might be challenging.

Aadiveer India Fab India ensures their polyester mesh fabrics meet the highest standards of durability, flexibility, and breathability. The company uses premium-grade polyester and advanced manufacturing techniques to deliver reliable products. Through this blog post, we at would like to share 10 important things to think about before choosing.

1. Mesh Dimensions

The mesh size, which is expressed in millimetres or microns, dictates how well the cloth filters particles. Greater airflow is made possible by larger mesh sizes, while finer filtering is made possible by smaller mesh sizes. We at Aadiveer Fab India Take into account the particular needs of your project and select a mesh size that strikes a balance between airflow and filtration effectiveness.

For example:

- A 100-mesh fabric has 100 holes per inch

- Lower mesh counts (20-50) are perfect for larger filtration needs

- Higher mesh counts (200+) work best for fine filtering or printing applications

Remember: The right mesh count depends entirely on your specific needs. Don’t automatically assume that higher is better!

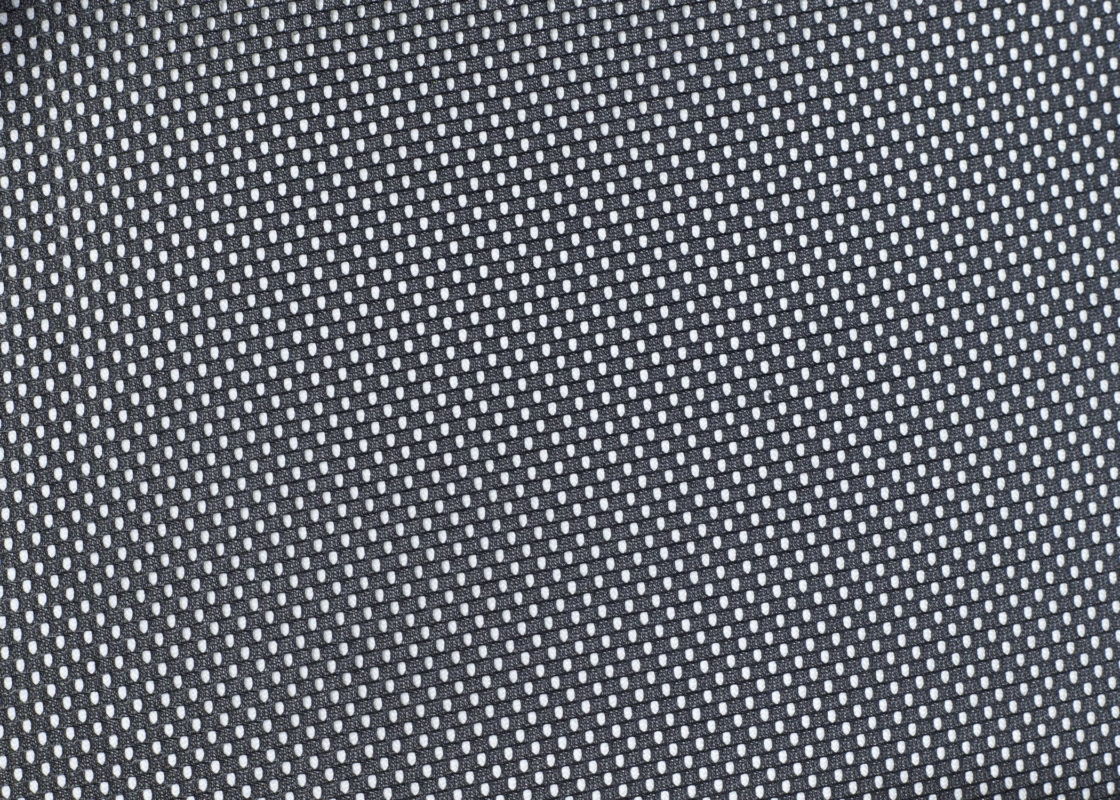

2. Thread Thickness / Diameter

The diameter of polyester threads impacts the fabric’s durability and flexibility. Thicker threads enhance strength for high-stress applications like conveyor belts, while thinner threads improve breathability and flexibility for sportswear or lightweight upholstery.

The Aadiveer Fab India Advantage: Our advanced weaving techniques allow precise control over thread thickness, delivering fabrics that balance robustness and comfort for your specific use cas

3. Fabric Weight

The weight of the fabric, measured in grams per square meter (gsm), influences its stiffness and drape. The weight impacts the fabric’s strength and feel:

- Lightweight fabrics (50–100 GSM) are ideal for clothing or decorative purposes.

- Medium to heavy fabrics (150–300 GSM) work better for industrial uses like conveyor belts or upholstery.

We offer a range of weights tailored to your project, ensuring durability without compromising flexibility.Select a weight that balances durability with flexibility for your project.

A heavier fabric is more durable and resistant to tearing, while a lighter fabric is more flexible and breathable. Consider the desired properties of the fabric and select a weight that aligns with your project’s needs.

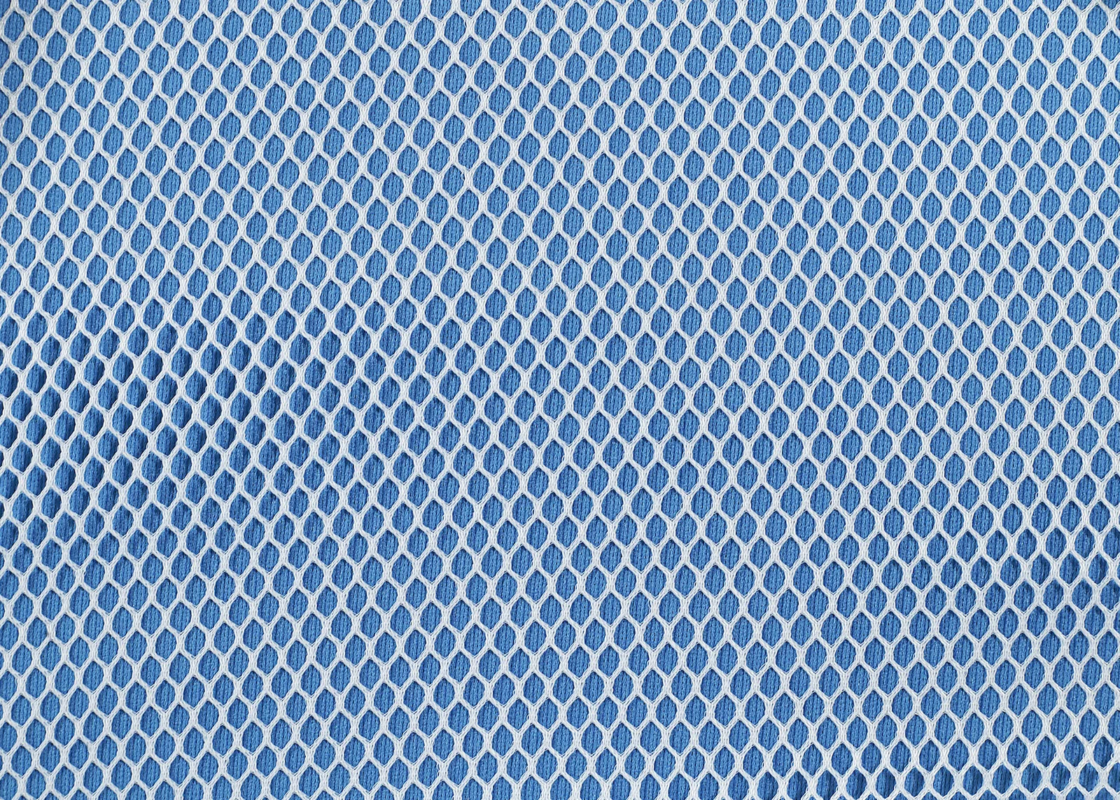

4. Color

Color can affect the fabric’s functionality even though it can appear to be solely an aesthetic choice. Since darker hues absorb more heat, they are appropriate for items like winter clothes when warmth is sought. Conversely, lighter hues reflect heat better, which makes them perfect for outdoor or summer clothing. We at Aadiveer Fab India, offer a diverse range of polyester mesh fabrics, catering to various applications such as sportswear, industrial filtration, upholstery, and outdoor gear.

5. UV Resistance

UV resistance is an important consideration if your project will be used outside. Over time, the cloth may get weaker and lose its color due to UV radiation degradation. To guarantee long-lasting performance, we ensure that our polyester mesh fabrics come with a high level of UV protection.

6. Chemical Resistance

The fabric may come into contact with different substances depending on its intended use. To avoid deterioration, we take into account the particular chemicals at play and curate quality fabric with sufficient chemical resistance.

7. Flame Retardancy

For projects in industries with fire hazards, flame-retardant polyester mesh fabric is essential. This type of fabric is treated with chemicals to reduce its flammability, making it safer for use in high-risk environments.

8. Breathability

Breathability is crucial for applications where airflow is essential, such as sportswear or industrial filtration. A breathable fabric allows moisture vapor to escape, keeping the wearer cool and dry. Look for mesh with larger pores or gaps if airflow is a priority. This is yet another functionality that we proritise during our fabric manufacturing process.

9. Cost

The cost of polyester mesh fabric varies depending on factors such as mesh size, thread thickness, fabric weight, and additional treatments. It’s important to balance cost with performance and select a fabric that meets your project’s needs without breaking the bank.

Additional Considerations

- Manufacturer Reputation: Choose a reputable manufacturer like Aadiveer Fab India with a proven track record of producing high-quality polyester mesh fabrics.

- Quality Control: Ensure that the fabric undergoes rigorous quality control testing to guarantee consistency and performance.

- Customization Options: Consider the availability of customization options, such as custom colors, patterns, and finishes.

- Environmental Impact: If sustainability is a concern, look for eco-friendly polyester mesh fabrics made from recycled materials or produced using sustainable manufacturing processes.

Conclusion

Choosing the right polyester mesh fabric for your project involves carefully evaluating factors like purpose, durability, breathability, and cost. By considering these ten points, you can ensure your fabric meets the demands of your project while staying within budget. Whether it’s for clothing, industrial use, or creative projects, the right polyester mesh fabric can make all the difference in achieving the desired results.

Aadiveer India Fab India stands out as a trusted supplier, offering fabrics that meet all these criteria. Their commitment to quality, innovation, and sustainability makes them the go-to manufacturer for polyester mesh fabrics.

When planning your next project, keep these factors in mind to make an informed decision and bring your project to life with the perfect polyester mesh fabrics from Aadiveer India Fab India!

Pingback: The Versatility of Fabric Mesh Netting Material in Modern Outdoor Gear